Building a single room is one of the most common construction projects in India, whether for home extensions, rental units, or independent living spaces. The cost of constructing a 10×10 room in India typically ranges from ₹1,50,000 to ₹3,50,000 depending on materials, location, and finish quality. Understanding the detailed breakdown of one room construction costs helps homeowners budget effectively and make informed decisions about materials and labor.

Understanding Single Room Construction

Table of Contents

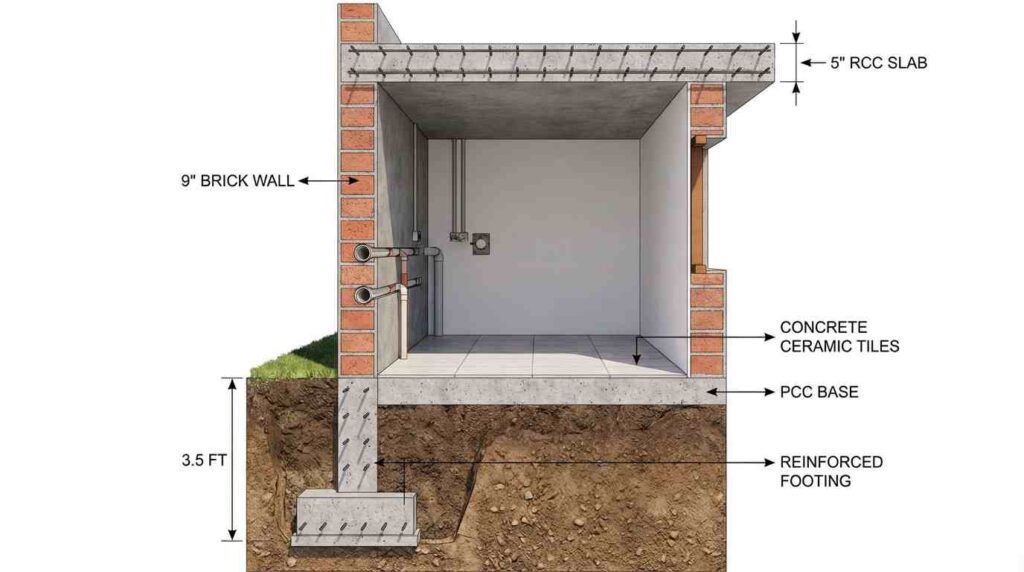

One room construction involves creating a self-contained space with foundational work, wall structures, roofing, and basic finishes. The standard 10×10 feet (100 sq ft) room serves as the benchmark for cost calculations across India, though actual dimensions may vary based on site conditions and requirements. This type of construction typically includes foundation laying, brickwork up to 10-12 feet height, RCC roof slab, plastering, flooring, door and window installation, and basic electrical and plumbing provisions.

The construction cost varies significantly based on three primary factors: material quality (economy, standard, or premium), geographic location (urban vs rural, metro vs tier-2 cities), and current market rates for materials and labor. In 2026, construction costs have seen moderate increases due to updated building codes, sustainable material requirements, and skilled labor shortages in certain regions.

| Construction Type | Cost Range (₹) | Per Sq Ft Cost | Suitable For |

|---|---|---|---|

| Economy Grade | ₹1,50,000 – ₹2,00,000 | ₹1,500 – ₹2,000 | Basic rental units, storage rooms |

| Standard Grade | ₹2,00,000 – ₹2,75,000 | ₹2,000 – ₹2,750 | Residential rooms, guest rooms |

| Premium Grade | ₹2,75,000 – ₹3,50,000 | ₹2,750 – ₹3,500 | High-end finishes, main bedrooms |

| Luxury Grade | ₹3,50,000+ | ₹3,500+ | Designer finishes, smart features |

🏗️ One Room Construction Cost Calculator

Calculate the estimated cost of constructing a single room based on dimensions and specifications

📏 Room Dimensions

🏡 Construction Quality & Materials

⚡ Additional Features

Foundation and Earthwork Costs

Foundation work forms the critical base of any construction and typically accounts for 15-20% of total room construction costs. For a 10×10 room, excavation depth ranges from 3-4 feet depending on soil conditions and load requirements. The foundation includes excavation work (₹8,000-₹12,000), PCC (Plain Cement Concrete) base layer (₹6,000-₹9,000), reinforced concrete footing (₹15,000-₹22,000), and plinth beam construction (₹18,000-₹25,000).

Site preparation involves clearing vegetation, leveling ground, marking layout, and ensuring proper drainage arrangements. In areas with weak soil conditions, additional work like soil compaction or extended foundation depth may increase costs by 20-30%. Modern construction in 2026 emphasizes soil testing before foundation work to prevent future settlement issues.

| Foundation Component | Quantity/Spec | Unit Cost (₹) | Total Cost (₹) |

|---|---|---|---|

| Excavation (3-4 ft depth) | 150-180 cu ft | 50-70/cu ft | 8,000-12,000 |

| PCC (1:4:8 mix) | 0.6-0.8 cu m | 10,000-12,000/cu m | 6,000-9,000 |

| Reinforced Footing | 0.8-1.2 cu m | 18,000-22,000/cu m | 15,000-25,000 |

| Plinth Beam (9″x9″) | 42 running ft | 420-600/ft | 18,000-25,000 |

| Plinth Filling | 80-100 cu ft | 100-150/cu ft | 8,000-15,000 |

Brickwork and Wall Construction

Wall construction represents 20-25% of the total one room building cost and involves multiple material choices. Standard 9-inch (230mm) brick walls are most common for load-bearing structures, while 4.5-inch walls may suffice for partition requirements. The typical 10×10 room with 10-foot height requires approximately 4,500-5,000 bricks for external walls and 2,000-2,500 for internal partitions if needed.

Red clay bricks remain popular (₹6-₹8 per piece), while fly ash bricks offer better thermal insulation (₹8-₹10 per piece) and AAC blocks provide lightweight alternatives (₹45-₹55 per block). Cement requirement for brickwork ranges from 15-18 bags (50kg each) with sand requirement of 1.5-2 brass (cubic meters). Labor costs for masonry work typically run ₹450-₹650 per square meter of wall area.

The mortar mix ratio varies from 1:5 to 1:6 (cement:sand) depending on wall type and load requirements. Modern construction increasingly uses machine-mixed mortar for consistency and quality control, adding approximately 5-8% to material costs but improving long-term durability.

| Wall Material Type | Unit Rate (₹) | Coverage | Material Cost | Labor Cost | Total/Sq M |

|---|---|---|---|---|---|

| Red Clay Bricks (9″) | 6-8/brick | 75 bricks/sq m | 450-600 | 400-550 | 850-1,150 |

| Fly Ash Bricks (9″) | 8-10/brick | 75 bricks/sq m | 600-750 | 400-550 | 1,000-1,300 |

| AAC Blocks (6″) | 45-55/block | 8-9 blocks/sq m | 360-495 | 300-400 | 660-895 |

| Concrete Blocks (8″) | 35-45/block | 12-13 blocks/sq m | 420-585 | 350-450 | 770-1,035 |

RCC Roof Slab Construction

The roof slab is often the most expensive single component, accounting for 25-30% of total construction costs. For a 10×10 room, a 4-inch to 5-inch thick RCC (Reinforced Cement Concrete) slab is standard, requiring approximately 1.2-1.5 cubic meters of concrete. The slab design must account for live load (150-200 kg/sq m), dead load (material weight), and safety factors as per IS 456:2000 building code requirements.

Materials for roof construction include cement (25-30 bags), sand (0.45-0.55 brass), aggregate (0.9-1.1 brass), reinforcement steel bars (150-180 kg of 8mm, 10mm, and 12mm TMT bars), and shuttering materials (plywood or steel). Concrete grade M20 or M25 is standard for residential roof slabs in 2026.

Labor costs for roof slab work include bar binding (₹45-₹60 per kg), shuttering and centering (₹180-₹250 per sq m), concrete pouring (₹250-₹350 per cubic meter), and curing for minimum 14 days. Many contractors now use ready-mix concrete (RMC) which costs ₹5,500-₹6,500 per cubic meter but ensures quality control and faster construction.

| Roof Component | Specification | Quantity Needed | Unit Cost (₹) | Total Cost (₹) |

|---|---|---|---|---|

| Cement (OPC/PPC) | 50 kg bags | 25-30 bags | 350-420/bag | 8,750-12,600 |

| Fine Sand | For concrete | 0.45-0.55 brass | 1,800-2,200/brass | 810-1,210 |

| Coarse Aggregate (20mm) | For concrete | 0.9-1.1 brass | 1,600-1,900/brass | 1,440-2,090 |

| TMT Steel Bars | Fe 500/550 grade | 150-180 kg | 65-75/kg | 9,750-13,500 |

| Shuttering Material | Rental/purchase | 100 sq ft | 40-60/sq ft | 4,000-6,000 |

| Labor for RCC Work | Complete roof | 100 sq ft slab | 300-450/sq ft | 30,000-45,000 |

| Total RCC Roof | ₹54,750-₹80,400 |

Plastering and Wall Finishing

Plastering provides smooth surfaces for painting and protects brickwork from weathering, typically costing ₹35,000-₹55,000 for a standard room. Internal plastering uses cement-sand mortar in 1:4 or 1:5 ratio with 12-15mm thickness, while external plastering requires 18-20mm thickness for better weather resistance and durability. Modern plastering increasingly incorporates polymer additives and waterproofing compounds for enhanced performance.

The process involves two coats: a base coat (dubbing) to level uneven surfaces and a finish coat for smoothness. Total wall area for a 10×10 room with 10-foot height including ceiling amounts to 500-550 sq ft. Material requirements include cement (12-16 bags), sand (0.8-1 brass), and water in proper proportions.

Alternatives to traditional plastering include gypsum plaster (faster drying, smoother finish, 15-20% more expensive), ready-mix plaster (consistent quality, reduced labor), and POP (Plaster of Paris) for ceilings. Labor rates range from ₹45-₹65 per sq ft for standard cement plastering and ₹65-₹90 per sq ft for specialized finishes.

| Plastering Type | Thickness (mm) | Material Cost/Sq Ft | Labor Cost/Sq Ft | Total Cost/Sq Ft | Room Total (500 sq ft) |

|---|---|---|---|---|---|

| Cement Sand (Internal) | 12-15 mm | 22-28 | 35-45 | 57-73 | ₹28,500-₹36,500 |

| Cement Sand (External) | 18-20 mm | 28-35 | 40-50 | 68-85 | ₹34,000-₹42,500 |

| Gypsum Plaster | 10-12 mm | 30-38 | 40-52 | 70-90 | ₹35,000-₹45,000 |

| Ready-Mix Plaster | 12-15 mm | 32-40 | 38-48 | 70-88 | ₹35,000-₹44,000 |

| POP (Ceiling only) | 6-8 mm | 35-45 | 45-60 | 80-105 | ₹8,000-₹10,500 (100 sq ft) |

Flooring and Tile Work

Flooring choices dramatically impact both cost and aesthetics, ranging from ₹18,000 for basic cement flooring to ₹80,000+ for premium materials. The standard sequence involves concrete base layer (50mm thick), sand bed or cement screed leveling, and final flooring material installation. Popular options in 2026 include vitrified tiles (most common), ceramic tiles (budget-friendly), marble (premium), granite (durable), and cement tiles (eco-friendly).

For a 100 sq ft room, material quantities vary by choice: vitrified tiles (110-115 sq ft accounting for wastage) at ₹40-₹120 per sq ft, ceramic tiles at ₹25-₹60 per sq ft, or marble/granite at ₹150-₹500 per sq ft. Installation requires tile adhesive or cement-sand mortar, grouting material, and edge finishing materials.

Labor charges for tile installation range from ₹35-₹55 per sq ft depending on tile size and pattern complexity. Large format tiles (2×2 feet or 2×4 feet) are trending in 2026 for fewer joints and modern aesthetics but require skilled installation. Waterproofing treatment under flooring adds ₹15-₹25 per sq ft but prevents future moisture issues.

| Flooring Type | Material Cost/Sq Ft | Installation Cost | Total Cost/Sq Ft | 100 Sq Ft Room | Durability |

|---|---|---|---|---|---|

| Cement Flooring | 12-18 | 18-25 | 30-43 | ₹3,000-₹4,300 | 5-8 years |

| Ceramic Tiles | 25-60 | 35-50 | 60-110 | ₹6,000-₹11,000 | 10-15 years |

| Vitrified Tiles (600x600mm) | 40-90 | 40-55 | 80-145 | ₹8,000-₹14,500 | 15-20 years |

| Vitrified Tiles (800x800mm) | 65-120 | 45-60 | 110-180 | ₹11,000-₹18,000 | 15-20 years |

| Granite | 120-250 | 50-70 | 170-320 | ₹17,000-₹32,000 | 20-30 years |

| Marble | 150-500 | 55-80 | 205-580 | ₹20,500-₹58,000 | 20-35 years |

| Wooden Flooring | 180-450 | 60-90 | 240-540 | ₹24,000-₹54,000 | 10-15 years |

Doors and Windows Installation

Door and window installations typically cost ₹15,000-₹45,000 depending on materials and specifications. A standard room requires one main door (7 feet × 3 feet) and one or two windows (4 feet × 3 feet or 5 feet × 3 feet) for ventilation and natural lighting. Frame materials include sal wood (most durable), teak (premium), pine (economical), or uPVC and aluminum (modern, low-maintenance).

Traditional wooden doors with frames cost ₹8,000-₹25,000 for main doors and ₹4,000-₹12,000 for flush doors, while uPVC doors range ₹12,000-₹22,000 and provide better thermal insulation. Window choices include basic steel windows (₹250-₹400 per sq ft), aluminum sliding windows (₹350-₹550 per sq ft), uPVC windows with double glazing (₹500-₹800 per sq ft), and designer wooden windows (₹600-₹1,200 per sq ft).

Installation costs include frame fixing, hardware (hinges, handles, locks), putty and painting for wooden items, and weatherproofing treatments. Modern building codes in 2026 mandate mosquito mesh provisions and grill work for ground floor windows, adding ₹150-₹250 per sq ft for grills.

| Door/Window Type | Specification | Material Cost | Hardware & Fitting | Total Cost |

|---|---|---|---|---|

| Teak Wood Main Door | 7′ × 3′ with frame | ₹18,000-₹25,000 | ₹2,500-₹4,000 | ₹20,500-₹29,000 |

| Sal Wood Main Door | 7′ × 3′ with frame | ₹10,000-₹16,000 | ₹2,000-₹3,500 | ₹12,000-₹19,500 |

| Flush Door (Internal) | 7′ × 3′ | ₹4,000-₹8,000 | ₹1,500-₹2,500 | ₹5,500-₹10,500 |

| uPVC Door | 7′ × 3′ | ₹12,000-₹20,000 | ₹1,500-₹2,500 | ₹13,500-₹22,500 |

| Aluminum Window | 4′ × 3′ sliding | ₹4,200-₹6,600 | ₹800-₹1,200 | ₹5,000-₹7,800 |

| uPVC Window | 4′ × 3′ | ₹6,000-₹9,600 | ₹800-₹1,400 | ₹6,800-₹11,000 |

| Steel Window | 4′ × 3′ | ₹3,000-₹4,800 | ₹600-₹1,000 | ₹3,600-₹5,800 |

| Window Grills | 12 sq ft | ₹1,800-₹3,000 | Included | ₹1,800-₹3,000 |

Electrical Wiring and Fittings

Electrical work involves concealed or exposed wiring, switch boards, power outlets, and lighting provisions costing ₹8,000-₹18,000 for basic installations. Standard wiring includes main supply cable (10 sq mm or 16 sq mm aluminum/copper), distribution wiring (2.5 sq mm for power points, 1.5 sq mm for lighting), PVC conduits, and MCB (Miniature Circuit Breaker) protection as per IE Rules 2026.

A typical room requires 4-6 power outlets (5 amp and 15 amp sockets), 2-3 light points, 1-2 fan points, and optional provisions for AC, geyser, or appliances. Copper wiring costs ₹25-₹35 per meter for 2.5 sq mm and ₹40-₹55 per meter for 4 sq mm, while aluminum costs 40-50% less but is less preferred now due to safety concerns.

Switch boards and accessories range from economy modular switches (₹50-₹100 per module) to premium brands like Legrand, Schneider, or Havells (₹150-₹400 per module). LED lighting fixtures cost ₹200-₹1,500 per point depending on design and brand. Professional electrician labor charges ₹300-₹500 per point for complete installation including testing.

| Electrical Component | Specification | Quantity | Unit Cost (₹) | Total Cost (₹) |

|---|---|---|---|---|

| Copper Wire (2.5 sq mm) | FR grade | 50-70 meters | 28-35/meter | 1,400-2,450 |

| Copper Wire (4 sq mm) | For power | 20-30 meters | 45-55/meter | 900-1,650 |

| PVC Conduits | Various sizes | 40-50 meters | 15-25/meter | 600-1,250 |

| MCB & Distribution Board | 4-6 way | 1 set | 1,800-3,500 | 1,800-3,500 |

| Modular Switches (Standard) | 5A/15A | 8-12 units | 80-150/unit | 640-1,800 |

| Power Sockets | 3-pin 15A | 4-6 points | 100-200/point | 400-1,200 |

| LED Light Fittings | Basic to standard | 2-3 points | 300-800/point | 600-2,400 |

| Fan Points with Regulator | Concealed wiring | 1-2 points | 400-700/point | 400-1,400 |

| Labor Charges | Complete work | 10-15 points | 300-500/point | 3,000-7,500 |

| Total Electrical | ₹9,740-₹21,150 |

Plumbing and Sanitary Work

Plumbing installations cost ₹6,000-₹15,000 depending on requirements and bathroom provisions. Basic room plumbing includes water supply piping, drainage connections, and optional provisions for attached bathroom or kitchenette. CPVC (Chlorinated Polyvinyl Chloride) pipes have become standard in 2026 for hot and cold water supply due to corrosion resistance and longevity.

Water supply piping uses 3/4-inch and 1/2-inch diameter CPVC or PPR pipes at ₹45-₹65 per meter for materials plus ₹25-₹40 per meter for installation. Drainage uses 3-inch and 4-inch PVC pipes (₹80-₹120 per meter) with proper slopes (1:40 to 1:60) for gravity flow. Connection to main sewage or septic tank requires 6-inch underground drainage pipes.

If including bathroom provisions, additional costs include sanitary fixtures (toilet, washbasin, taps), overhead water tank connection, bathroom fittings, and waterproofing treatments. Basic bathroom fittings package costs ₹8,000-₹25,000 for economy to standard quality. Professional plumber charges ₹400-₹600 per day with projects typically requiring 2-4 days.

| Plumbing Element | Material/Type | Quantity | Rate (₹) | Amount (₹) |

|---|---|---|---|---|

| CPVC Pipes (3/4″ & 1/2″) | Supreme/Astral | 20-30 meters | 50-65/m | 1,000-1,950 |

| PVC Drainage Pipes (3″) | For waste | 10-15 meters | 85-110/m | 850-1,650 |

| PVC Pipes (4″ main drain) | Underground | 8-12 meters | 120-160/m | 960-1,920 |

| Pipe Fittings & Accessories | Elbows, tees, etc. | Assorted | Lump sum | 1,200-2,000 |

| Water Tap Points | Brass/CP fittings | 2-3 points | 400-800/point | 800-2,400 |

| Bathroom Fixtures (if included) | Basic set | 1 set | 8,000-15,000 | 8,000-15,000 |

| Labor Charges | Plumber wages | 3-5 days | 500-700/day | 1,500-3,500 |

| Total Plumbing (Basic) | ₹6,310-₹13,420 | |||

| Total with Bathroom | ₹14,310-₹28,420 |

Painting and Final Finishes

Painting provides the final aesthetic touch and protection to walls and ceilings, costing ₹12,000-₹28,000 for a complete room. The process involves wall preparation (putty application), primer coat, and two finish coats of emulsion or enamel paint. Wall putty smoothens surfaces and fills minor imperfections, requiring 1.5-2 kg per sq meter at ₹300-₹450 for 20-25 kg bags.

Interior emulsion paints from economy brands (Asian Paints Tractor, Birla White) cost ₹150-₹250 per liter covering 120-140 sq ft per liter, while premium options (Asian Paints Royale, Dulux Premium) cost ₹400-₹700 per liter with better coverage and finish. Exterior paints require weather-resistant formulations costing ₹200-₹500 per liter.

Labor charges for painting vary from ₹12-₹18 per sq ft for basic work to ₹20-₹30 per sq ft for textured or designer finishes. Total paintable area for a 10×10 room including walls and ceiling ranges from 500-550 sq ft. Additional finishing touches include skirting (₹35-₹75 per running foot), corner beadings, and decorative moldings.

| Painting Element | Specification | Coverage/Quantity | Rate (₹) | Cost (₹) |

|---|---|---|---|---|

| Wall Putty (White cement based) | 20-25 kg bag | 1-1.5 bags | 350-450/bag | 350-675 |

| Primer Coat | Acrylic/synthetic | 4-5 liters | 120-180/liter | 480-900 |

| Economy Emulsion Paint | 2 coats | 8-10 liters | 180-250/liter | 1,440-2,500 |

| Standard Emulsion Paint | 2 coats | 7-9 liters | 300-450/liter | 2,100-4,050 |

| Premium Emulsion Paint | 2 coats | 6-8 liters | 500-700/liter | 3,000-5,600 |

| Enamel Paint (Doors/Windows) | Wood surfaces | 1-2 liters | 350-500/liter | 350-1,000 |

| Labor – Basic Painting | 500-550 sq ft | 550 sq ft | 12-18/sq ft | 6,600-9,900 |

| Labor – Premium Finish | 500-550 sq ft | 550 sq ft | 20-30/sq ft | 11,000-16,500 |

| Skirting/Dado Work (optional) | 42 running feet | 42 ft | 40-75/ft | 1,680-3,150 |

Regional Cost Variations

Construction costs vary significantly across different Indian regions due to material availability, labor rates, and transportation expenses. Metropolitan cities like Mumbai, Delhi, Bangalore, and Chennai typically see 25-40% higher costs than tier-2 and tier-3 cities. Rural areas may have lower labor costs but higher material transportation expenses, sometimes balancing overall costs.

Northern states (Delhi NCR, Punjab, Haryana) show higher costs for skilled labor (₹600-₹800 per day) compared to southern states (₹450-₹650 per day). Coastal areas require better weatherproofing and corrosion-resistant materials, adding 10-15% to standard costs. Hill stations and remote areas face 30-50% material transportation surcharges.

In 2026, the government’s push for sustainable construction has led to incentives for green materials and energy-efficient designs in major cities. States like Kerala, Karnataka, and Maharashtra offer building approval fee reductions (5-10%) for constructions using minimum 30% sustainable materials or incorporating rainwater harvesting and solar provisions.

| Region/City Type | Labor Rate/Day (₹) | Material Premium | Overall Cost Factor | 10×10 Room Range (₹) |

|---|---|---|---|---|

| Metro Cities (Tier-1) | 600-850 | 15-25% higher | 1.30-1.45× | 1,95,000-3,50,000 |

| Tier-2 Cities | 500-700 | 5-15% higher | 1.10-1.25× | 1,65,000-2,75,000 |

| Tier-3 Towns | 450-600 | Base rates | 1.00-1.10× | 1,50,000-2,40,000 |

| Rural Areas | 400-550 | 10-20% transport cost | 1.05-1.20× | 1,58,000-2,50,000 |

| Coastal Regions | 500-700 | 10-15% weatherproofing | 1.15-1.30× | 1,73,000-2,85,000 |

| Hill Stations | 550-750 | 25-40% transport cost | 1.35-1.50× | 2,03,000-3,30,000 |

Cost-Saving Strategies

Reducing construction costs without compromising quality requires strategic planning and material selection. Purchasing materials during off-season or festive sales can save 8-15% on bulk items like cement, steel, and tiles. Buying directly from manufacturers or wholesale dealers eliminates middleman margins, potentially reducing costs by 10-20% for major materials.

Labor cost optimization includes hiring a single contractor for multiple tasks rather than separate specialists, negotiating package rates (typically 10-15% cheaper), and scheduling work during lean construction seasons (monsoon months) when labor rates drop. Using locally available materials reduces transportation costs and supports regional economy while maintaining quality standards.

Alternative construction methods gaining popularity in 2026 include prefabricated wall panels (20-30% faster, 10-15% cheaper for large projects), AAC blocks instead of traditional bricks (lighter, better insulation, comparable costs), and ready-mix concrete for roof slabs (quality consistency, time savings). However, extremely cheap materials or unskilled labor often lead to higher maintenance costs and shorter building lifespan.

| Cost-Saving Strategy | Potential Savings | Implementation | Considerations |

|---|---|---|---|

| Bulk Material Purchase | 10-15% | Buy cement, sand, aggregate together | Requires storage space |

| Off-Season Construction | 8-12% | Schedule during monsoon (June-Sept) | Weather delays possible |

| Direct Manufacturer Purchase | 10-20% | Skip retailers for major items | Requires bulk quantities |

| Standard Size Materials | 5-8% | Use standard tile sizes, door dimensions | Limits design flexibility |

| Local Materials | 12-18% | Source bricks, sand, aggregate locally | Check quality standards |

| Package Contractor Deal | 10-15% | Single contractor for all work | Ensure clear contract terms |

| AAC Blocks vs Bricks | 5-10% | Lightweight blocks | Requires trained masons |

| Eliminated Wastage | 8-12% | Accurate measurements, proper storage | Needs site supervision |

| Standard Fixtures | 15-25% | Economy/standard brands vs premium | Quality may vary |

Common Mistakes to Avoid

Poor planning and execution errors can inflate construction costs by 20-40% through rework and corrections. The most critical mistake is inadequate foundation work, leading to cracks and settlement issues within 2-3 years. Foundation depth must match soil conditions with proper reinforcement; saving ₹5,000-₹10,000 here often costs ₹50,000+ in future repairs.

Using substandard materials, especially cement, steel, and bricks, compromises structural integrity and longevity. Cement should be tested for authenticity (ISI mark), used within three months of manufacturing, and stored properly to prevent moisture exposure. Steel bars must meet Fe 500 or Fe 550 standards with proper rust prevention during construction.

Inadequate waterproofing in foundation, roof, and bathroom areas leads to seepage, dampness, and structural damage. Waterproofing treatment costs ₹8,000-₹15,000 for a room but prevents damage repairs costing ₹40,000-₹80,000 later. Other common errors include poor ventilation planning, incorrect electrical load calculations, improper drainage slopes, and skipping building plan approvals which can lead to demolition notices.

| Common Mistake | Immediate Saving | Future Cost Impact | Correct Practice |

|---|---|---|---|

| Shallow Foundation | ₹8,000-₹12,000 | ₹50,000-₹1,00,000 | Follow soil test recommendations |

| Substandard Cement | ₹30-₹50/bag | Weak structure, cracks | Use ISI marked OPC/PPC only |

| Insufficient Steel | ₹5,000-₹10,000 | Structural weakness | Follow structural design specs |

| No Waterproofing | ₹10,000-₹18,000 | ₹60,000-₹1,20,000 | Apply in foundation, roof, bathroom |

| Poor Drainage Slope | ₹2,000-₹4,000 | Water stagnation, repairs | Maintain 1:60 to 1:40 slope |

| Hiring Unskilled Labor | ₹100-₹200/day | Rework costs 30-50% | Verify experience, check references |

| Skipping Curing | ₹2,000-₹3,000 | Weak concrete, cracks | Cure for minimum 14 days |

| No Building Approval | ₹5,000-₹15,000 | Demolition risk, legal issues | Obtain permissions before starting |

Modern Trends and Technologies

Construction technology in 2026 emphasizes sustainability, efficiency, and smart features even in single-room projects. Green building materials like fly ash bricks, recycled aggregates, and low-VOC paints reduce environmental impact while maintaining cost competitiveness. Solar-ready electrical provisions add ₹3,000-₹6,000 initially but enable future solar panel installation for long-term energy savings.

Smart home integration includes IoT-enabled switches, motion sensor lighting, and app-controlled fans, adding ₹5,000-₹15,000 to electrical costs but providing convenience and energy management. Prefabricated door and window frames ensure precision fitting and reduce installation time by 30-40%. Modular electrical and plumbing systems allow easier future modifications without breaking walls.

Energy-efficient design features include double-glazed windows for thermal insulation (15-20% higher cost, 30% better insulation), reflective roof coatings to reduce heat absorption (₹25-₹40 per sq ft), and proper orientation for natural ventilation. Rainwater harvesting provisions, though not always necessary for single rooms, cost ₹4,000-₹8,000 and provide water security while meeting green building norms in many cities.